Our,Sina Pazhouhan Company Validation-ISO-GMP

Validation

In order to produce products with the best quality, Sina Pazhouhan Pharmaceutical Company has a written program according to the protocols of the Food and Drug Organization and the international laws of the World Health Organization (WHO) and ISO to check the validation of all its departments and adheres to it.

ISO stands for International Organization for Standardization. It is a global non-governmental organization composed of representatives of national standardization institutions that work in the departments related to the development of international standards, and its purpose is to integrate and coordinate all processes and procedures for doing things according to international standards.

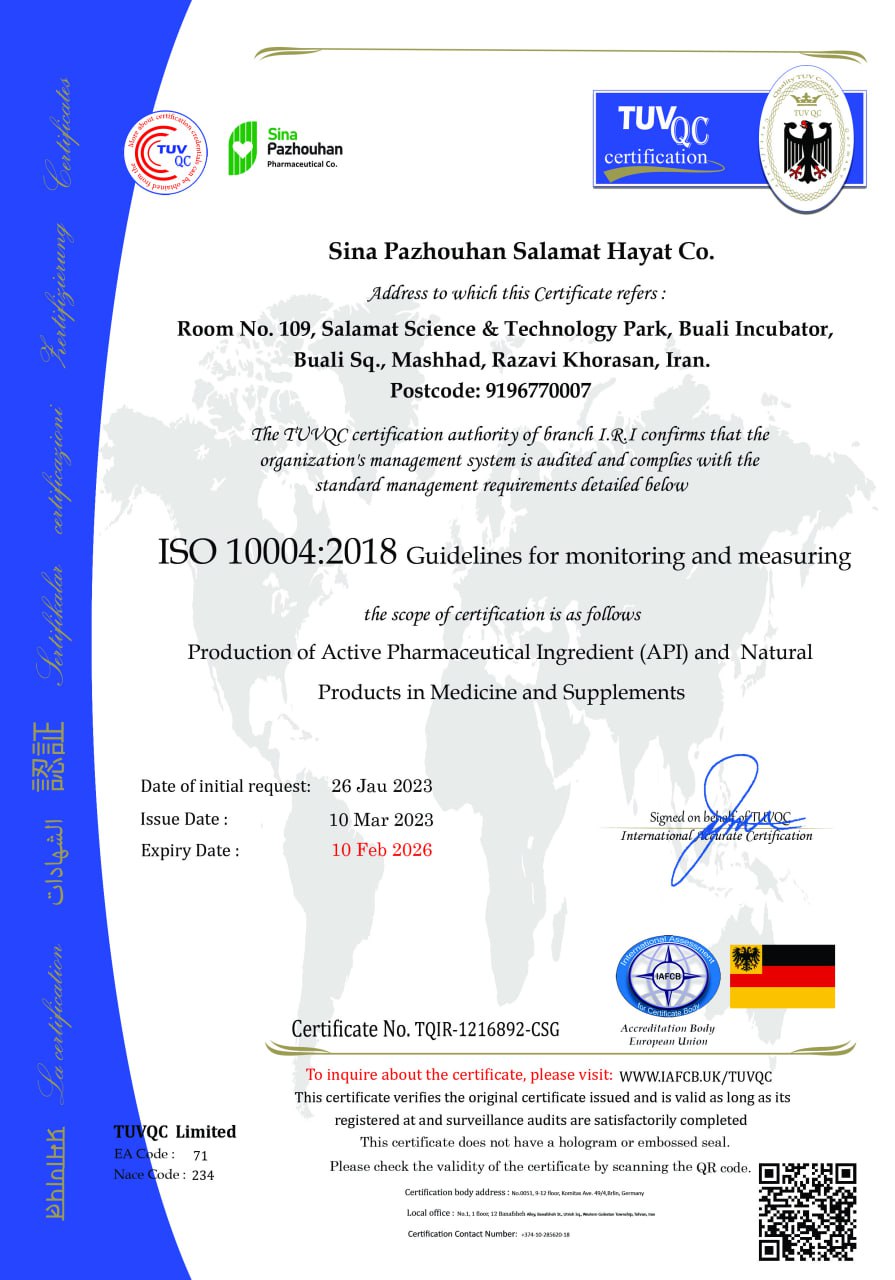

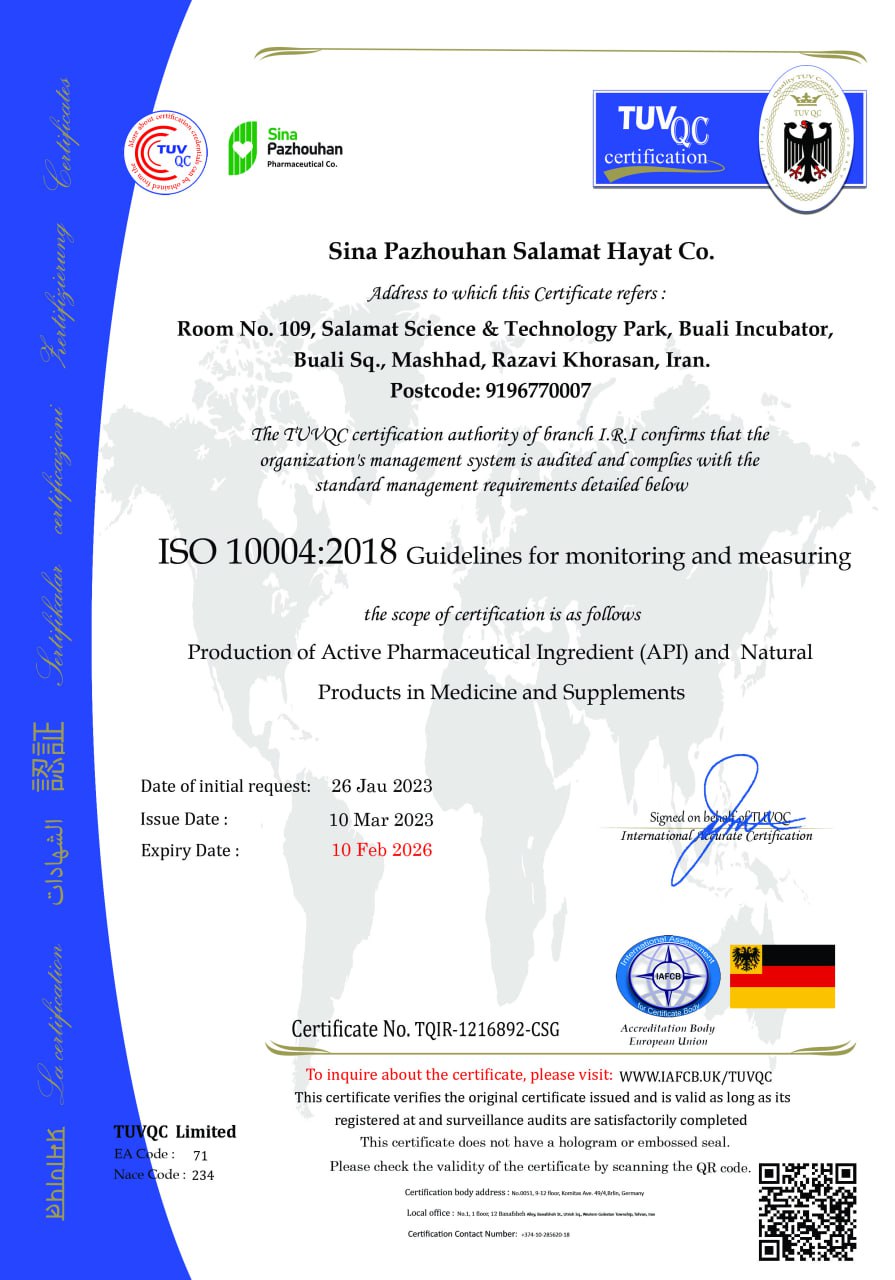

In the field of production of pharmaceutical products and raw materials, over the years, agents of different countries set standards for improving services and products by holding numerous meetings. These standards are international and their compliance is mandatory for improvement and integration. Sina Pazhouhan Pharmaceutical Company has been able to obtain ISO 9001:2015 certification in the field of quality management system and ISO 10004:2018 certification in the field of customer satisfaction.

GMP is part of the quality management system that ensures pharmaceutical products are always manufactured and tested according to quality standards and are suitable for use. GMP includes criteria that apply to both production and laboratory.

-

Equipment, tools and building should be prepared, designed and used correctly.

-

The works should be recorded in the instructions part by part and step by step.

-

Do the work according to the written instructions.

-

Perform activities and the results are recorded and maintained.

-

Validate processes and activities.

-

Tools and devices are under control.

-

Materials and processes related to product production are controlled and pollution is prevented.

-

Design, plan and execute inspections.

GMP

GMP

Sina Pazhouhan Pharmaceutical Company has created and established a dedicated department to implement GMP rules according to PIC/S rules in its production and laboratory unit, which assures the consumer that the company will adhere to its promise to supply a good and high quality product .

It should also be noted that according to the Law of Medical Products, the laboratories of Sina Pazhouhan Company, under the supervision of the Food and Drug Organization of Iran, which governs the pharmaceutical industry, are legally required to comply with Good Laboratory Practice (GLP) standards. GLP means adherence to strict criteria such as:

-

Test method assurance: validation and control

-

Instrument calibration and maintenance programs

-

Standard quality control

-

Allowed materials and product specifications

-

Data quality, integrity and accuracy

regulatory

Our world-leading understanding of all these quality issues and years of experience in quality control at Sina Pazhouhan ensure that our customers always receive effective services and superior quality products.

Validation

In order to produce products with the best quality, Sina Pazhouhan Pharmaceutical Company has a written program according to the protocols of the Food and Drug Organization and the international laws of the World Health Organization (WHO) and ISO to check the validation of all its departments and adheres to it.

ISO stands for International Organization for Standardization. It is a global non-governmental organization composed of representatives of national standardization institutions that work in the departments related to the development of international standards, and its purpose is to integrate and coordinate all processes and procedures for doing things according to international standards.

In the field of production of pharmaceutical products and raw materials, over the years, agents of different countries set standards for improving services and products by holding numerous meetings. These standards are international and their compliance is mandatory for improvement and integration. Sina Pazhouhan Pharmaceutical Company has been able to obtain ISO 9001:2015 certification in the field of quality management system and ISO 10004:2018 certification in the field of customer satisfaction.

GMP

GMP

-

Equipment, tools and building should be prepared, designed and used correctly.

-

The works should be recorded in the instructions part by part and step by step.

-

Do the work according to the written instructions.

-

Perform activities and the results are recorded and maintained.

-

Validate processes and activities.

-

Tools and devices are under control.

-

Materials and processes related to product production are controlled and pollution is prevented.

-

Design, plan and execute inspections.

-

Test method assurance: validation and control

-

Instrument calibration and maintenance programs

-

Standard quality control

-

Allowed materials and product specifications

-

Data quality, integrity and accuracy

regulatory

Our world-leading understanding of all these quality issues and years of experience in quality control at Sina Pazhouhan ensure that our customers always receive effective services and superior quality products.